Our welding cabins are designed to meet every need, no matter the complexity of your project. We offer customized solutions that are safe, reliable and of the highest quality.

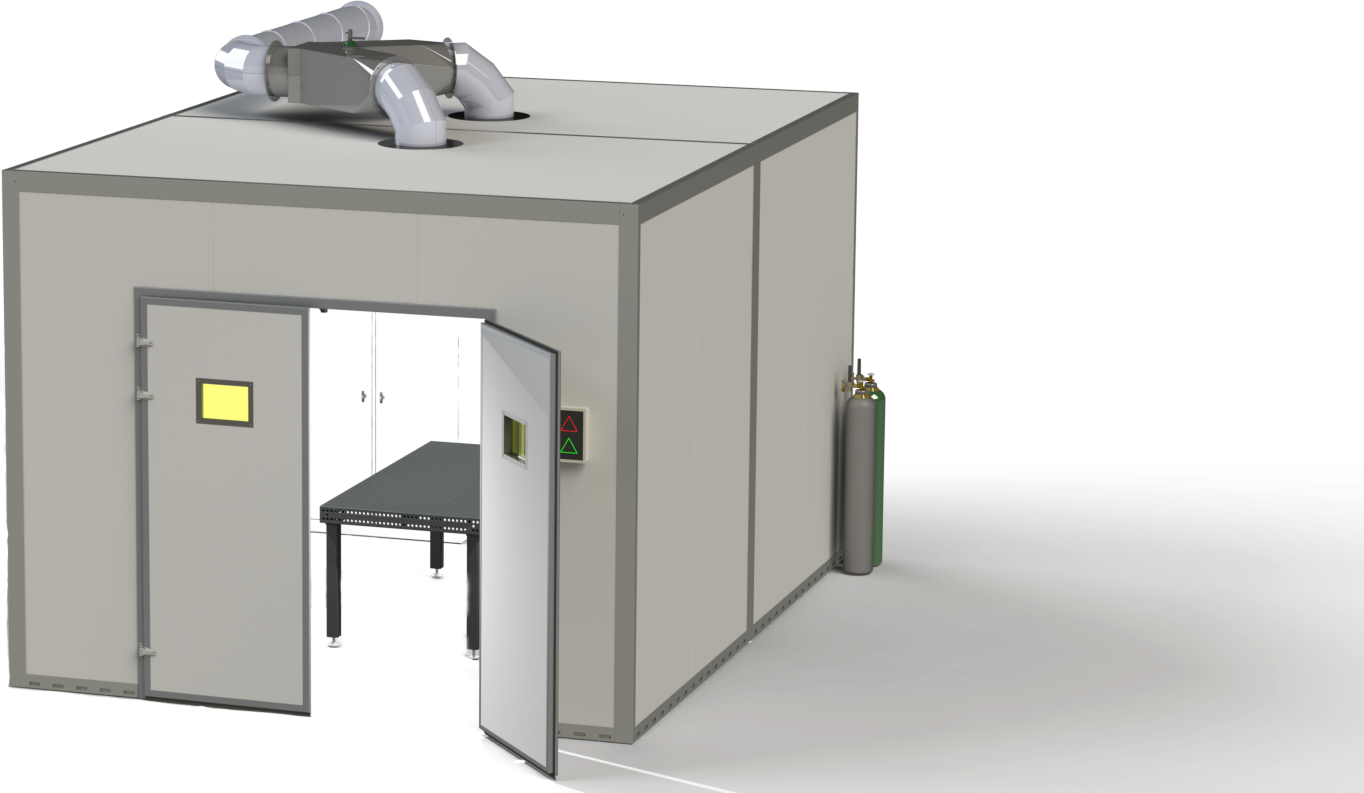

This welding cabin is designed and made by welding specialists. Originated from our own needs, where productivity, convenience and quality are paramount. Due to the modular design, this cabin can be configured according to customer requirements, making it suitable for various applications. Certified according the international laser safety standard IEC 60825-1:2014.

Certified for safety, extremely suitable for laser welding.

Make your cobot extra safe with a cabin with integrated extraction.

An organized welding department with the best conditions.

Very suitable for carrying out measuring activities.

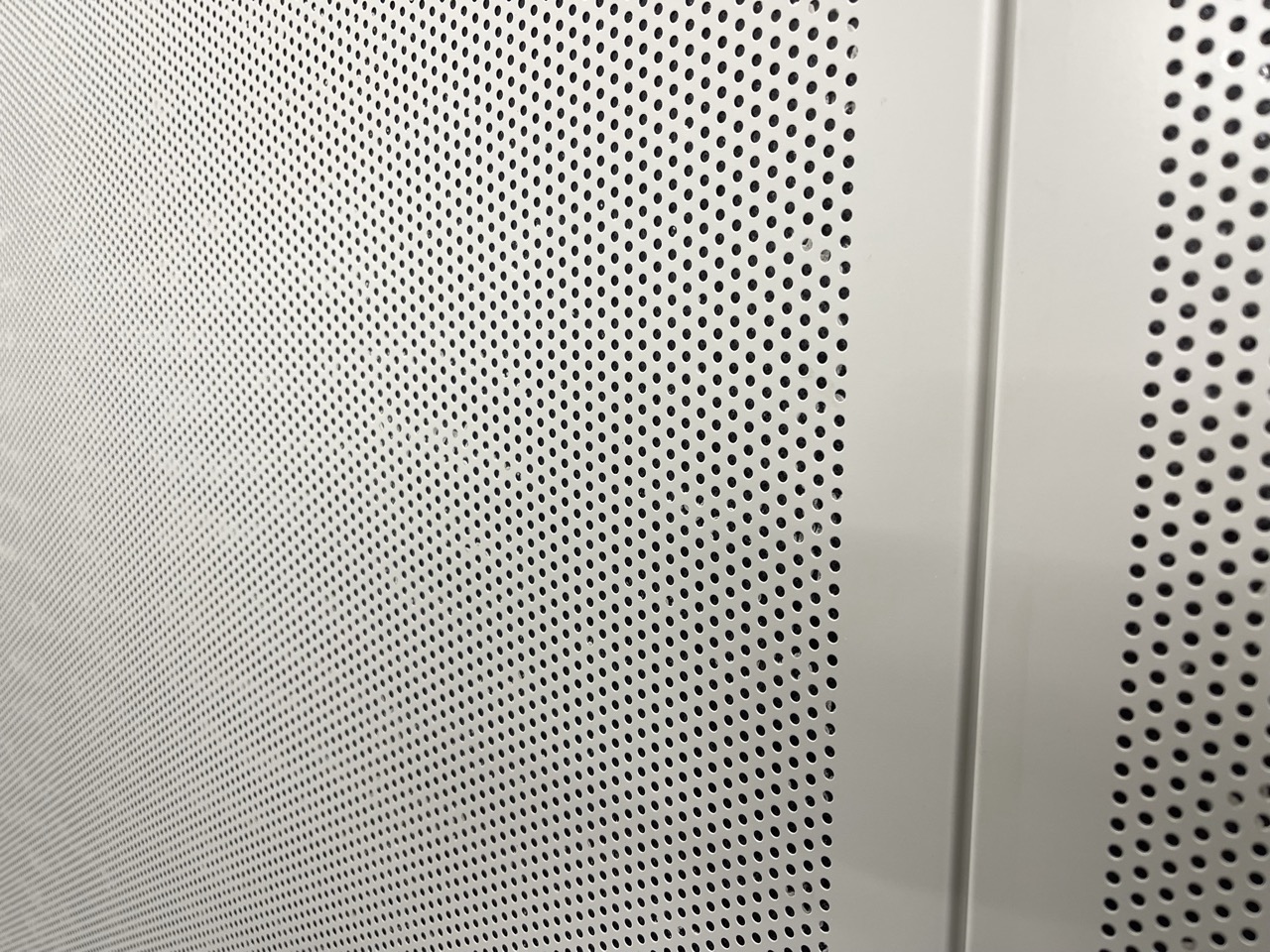

The walls are made of perforated sandwich panels with a rock wool core for optimal sound absorption. Despite the perforation, the panel remains strong and fireproof. The standard size is 3.7 x 4.9 x 3 meters, other sizes are also available. Standard color RAL9002

The cabin can be put together according to customer wishes. Due to the modular construction, different sizes with all kinds of options can be selected. In this way, the cabin can be made specifically suitable for your application. View all options here:

This cabin is the ideal solution for us to be able to carry out manual laser welding in a safe, enclosed space. Another advantage is that we can immediately make good separations between different materials such as steel, stainless steel and aluminum. We have installed the cabin in the welding department. extensively tested for laser welding and incorporated this feedback into the further development of the cabin.

Welding specialist Berto Iprenburg

WE-Metal B.V.

We are happy to talk to see what we can do for you. Leave your details and we will contact you as soon as possible. We are also open to cooperation with integrators, suppliers of welding equipment or other resellers.

We're happy to think along with you